Home > Georgia > Georgia Crops & Livestock > Georgia Egg Farms Evolve

Georgia Egg Farms Evolve

Second-generation egg farmer Brent Booker thought he had life figured out as a teenager with a vision that didn’t involve chickens.

Now, he owns more than 1 million of them.

“I didn’t want to be in the family egg business at first,” says Booker, president of Country Charm Egg LLC in small-town Gillsville. “After college I worked a year off the farm and then came back. It’s one of those things in my blood. I started to realize how important it was and how special it was to be in a family farming business. Hopefully my kids will continue as the third generation.”

Today, Booker and 110 employees care for 1.7 million laying hens that produce around 36 million dozen eggs annually in a highly technical industry that has adapted to better laying conditions and improved processes.

“These days, the first human hand to touch the egg is really the consumer at home,” Booker says.

Technology Improves Conditions, Efficiencies

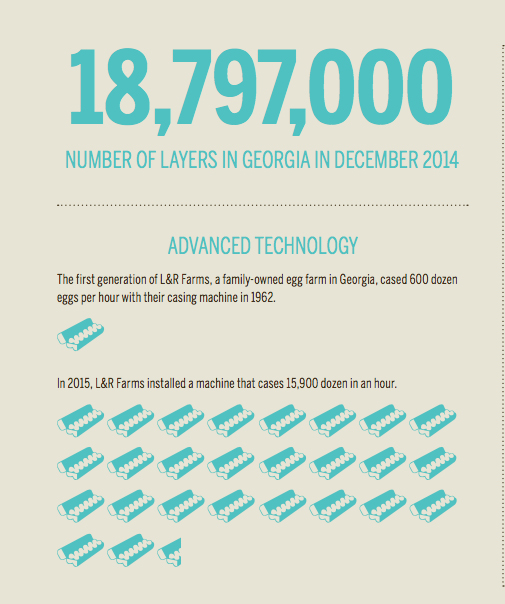

Georgia’s egg farmers represent a mighty few. The number of commercial egg farms throughout Georgia dropped from around 450 in the late 1970s to fewer than 10 today, says second-generation egg farmer David Lathem. Still, Georgia ranks sixth in the nation in the number of laying hens, according to the National Agricultural Statistics Service. Georgia farmers in 2014 produced 4.7 billion eggs valued at nearly $666 million.

“You have to grow to keep up and keep your costs down,” says Lathem, president of L&R Farms Inc. His family’s egg business owns 1.5 million layers, employs 60 people and annually produces 30 million dozen eggs near Pendergrass.

“That’s really what it took to be competitive – adopt new technology and continuously improve.”

Among the biggest changes for bird health and efficiencies came with moving chickens from the floor and into cages, Lathem says. The change netted cleaner conditions and reduced bird illness, among other benefits.

Early in his farming career, Lathem reached his dream to own an in-line complex, which means hen houses are attached to the egg processing plant. Just a few years ago, he also built an impressive organic operation from scratch after extensive study, which included visits to the West Coast and European countries.

Common throughout the industry, computers control the hen houses, a move that made significant strides to maintain comfortable temperatures for hens and manage lighting schedules, Lathem says.

L&R Farms also has begun to adopt LED lighting, which saves energy, cuts the electric bill and improves production potential. Light stimulates chickens to lay, and LED lights more successfully replicate sunrise and sunset with their dimming qualities, Lathem says. In fact, the University of Georgia noted this in recent research on LED use in hen houses.

Egg Farms Evolve

Whether the subject is for feed access, beak trimming or amount of space, regulations and industry demands, as well as available technology, have prompted egg farmers to evolve.

“Over the last 10 to 15 years, a lot of things have changed in the industry,” Booker says. “We follow what is called the United Egg Producers animal welfare guidelines. They have a compliance plan that really guidelines everything from handling to how much room hens have.”

L&R Farms also complies with various animal husbandry programs. In fact, compliance represents the daily role of Lathem’s son in the business.

Meanwhile, a nephew handles information technology, from the farm’s office computers to hen house automation. His son in high school expresses interest in the family farm, too.

“I’ve worked in the business all my life. I enjoy working and want to work more,” Lathem says, “but the thought that my family can carry on the business gives me a lot of drive to stay active so they can learn the business and take it over.”