Home > Virginia > Virginia Environment > Virginia Forest Industry Focuses on Sustainability, Reforestation

Virginia Forest Industry Focuses on Sustainability, Reforestation

In partnership with: Virginia Department of Agriculture and Consumer Services

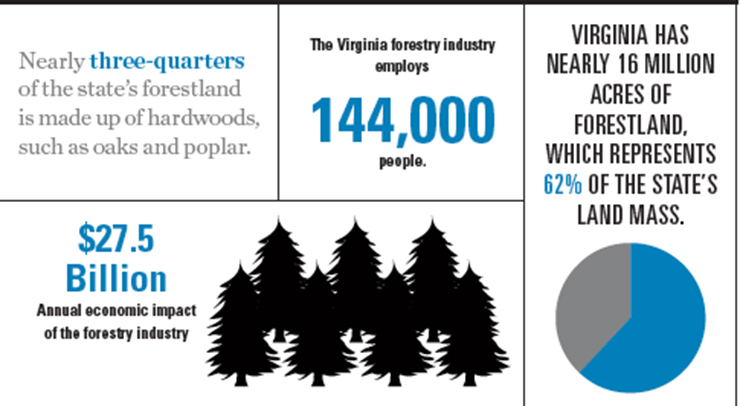

The nearly 16 million acres of forestland in Virginia create a beautiful landscape across the state. But those acres also create much more. They provide environmental benefits, by cleansing the air and purifying the water. They offer exceptional recreation opportunities for residents and visitors alike. And the valuable natural resource provides significant economic benefits through timberland production and the industries that depend on it. In Virginia, that economic impact is estimated at $30 billion each year.

According to Charles Becker, the utilization and marketing manager for the Virginia Department of Forestry (DOF), the forest products industry in the state has a long and proud tradition dating back to Jamestown, when the wood was used for shipbuilding and construction.

Today, the timber has a myriad of additional uses, including furniture production, pulp and paper, boxes, pallets, shipping crates, and wood pellets for heating. Becker explains that nearly three-quarters of the state’s forestland is made up of hardwoods, such as oaks and poplar, most of that in western Virginia and the mountainous areas. The southern and eastern parts of the state produce softwoods, like pines and other conifers. In addition, a unique area in southwest Virginia has long been known for the quality of its white pine.

“The traditional products are still the backbone of the forestry industry,” says Becker, who works to develop markets for Virginia forest landowners and businesses. “But we are also exporting more timber to countries like China, for instance. And we are always exploring new opportunities and new products. Ten years ago, we didn’t have any plants producing wood pellets and now we have eight or nine in the state. Cross-laminated timber, which is using lumber to make large panels that can substitute for concrete walls, has become popular in Canada and Europe and a new opportunity for us.”

Growing Partnerships

Managing the forestland is critical to ensuring the continuation of these many environmental and economic benefits, says Harvey Darden, the director of state lands for the Virginia DOF.

“We want to make sure we have forests and timber for future generations, which means they need to be managed sustainably,” he says.

The DOF has several initiatives in place to do that. First, is the state lands program, which includes managing 68,000 acres of state forests and growing nearly 28 million seedlings at state nurseries. The programs, explains Darden, are self-supporting and receive no tax dollars. The 22 state forests, which each have a 10-year management plan, harvest timber and sell it like the state’s private landowners do. The state nurseries grow more than 2 million hardwood seedlings and 25 million loblolly pine trees, 99 percent of which are sold to the public for reforestation purposes.

The state lands program also shares their knowledge with private landowners and companies.

“We bring groups into our state forests and show them how they can apply the same techniques and processes we use on their timberland,” Darden says. “We also work with landowners who wish to put a conservation easement on their property, so they can protect their property from any future development and ensure its use as timberland.”

Furniture makers and paper companies that make use of the forest for their products also play a role in protecting this valuable natural resource. For instance, Vaughan-Bassett Furniture Company has initiated a “One-for-One” program. “The company contributes funds to purchase seedlings that are then given away. This is a way that they commit to replenish the forest, by contributing the same number of seedlings as the number of trees that were used to make their products,” Darden explains.

He also mentions similar efforts by Belfort Furniture and Plow & Hearth, a home and outdoor living retailer that donates two times the number of trees used to produce their catalogs. Paper companies like New Page and Glatfelter donate funds for seedlings as well.

“We need to be growing more wood than we harvest,” says Becker. “And good forest management practices and efforts like these by the industry ensures we have sustainable working forests for the future.”

Managing for the Future

Norman Pate is a procurement forester with Augusta Lumber, a division of American Hardwood Industries. He travels across the state buying quality poplar and oak tracts. The quality hardwood timber is used by his company to make flooring and furniture.

He describes the importance of efforts like SHARP certification, which is a part of the forest sustainability initiative. Pate explains that it is an educational program administered by Virginia Tech and hosted by mills, including Augusta’s. “By teaching loggers how to cut logs for better grade, you create more efficiencies and less wasted product,” says Pate.

Reforestation efforts are also important, although Pate explains that “if you clean cut a stand of hardwood, everything you cut will begin to grow back over 60 to 80 years, so that’s a natural reforestation. Pines, on the other hand, must be replanted because if left to natural reforestation a stand of pine trees will grow back in mixed pine and hardwood because of much of Virginia’s land is hardwood.”

In the mountainous areas of the state, where they don’t have the concern about hurricanes damaging trees, select cutting is also done as a way to make the most of the timber resource. “It’s a process where you go out and cut selected mature hardwood trees out of a stand,” says Pate. “This allows the suppressed trees to become the dominant trees, which then can be cut in 15 to 20 years.”

It’s forestry management practices like this and the many other efforts of both the private and public sectors that create a strong industry in Virginia. “We have a good growing resource in the state,” says Pate, “and a lot of people who are committed to keeping it that way.”