Home > Georgia > Georgia Crops & Livestock > Cotton Takes Top Spot in Georgia Row Crops

Cotton Takes Top Spot in Georgia Row Crops

Love those blue jeans? You have a cotton farmer to thank.

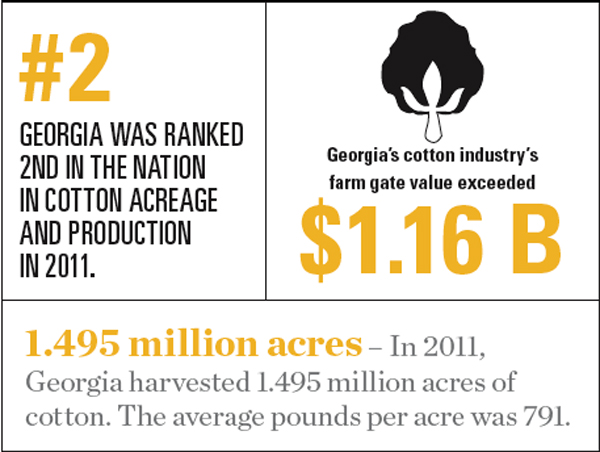

Georgia cotton farmers produce 2.2 million bales of cotton every year, enough to rank cotton as the number-two commodity in the state. And as for those favorite jeans, it takes 24 ounces of cotton to make one pair.

Chuck Coley takes his cotton seriously. He’s chair of the National Cotton Council, and has been a cotton farmer all his life. He’s proud that Georgia is second in the nation in cotton production, just behind Texas.

“I think cotton production gets in your blood,” Coley says. “There’s a lot of good people in the industry. In my operation, we raise two crops – cotton and peanuts – and we always will.”

Like a well-worn pair of jeans, cotton production has had a few rips in its lifetime. The crop’s history in the state hasn’t been without some hardships.

“Back in the early ’20s and ’30s, Georgia farmers planted over 5 million acres,” Coley says. “Then came the boll weevil, and cotton production nearly left Georgia.”

The arrival of the beetle, which feeds on cotton buds and flowers, devastated the cotton crop in the state. To recover, Georgia farmers started raising more traditional Midwestern crops like corn, soybeans and wheat.

It took until the early 1980s, when scientists came up with the tools to eradicate the pesky boll weevil that cotton production begin to return as a major crop in the state. Thanks to the Boll Weevil Eradication Program, none of these beetles have been found in the state since 2002.

Around the same time, cotton plants were engineered to be resistant to pests.

“We used to have to spray our crop 18 to 20 times a year,” Coley says of keeping insects off the crop. “Now with our GMO plants, we may spray two times at the most.”

Changes for the Industry

In 2010, cotton retained its position as one of the leading cash row crops in Georgia, with production of 2.2 million bales of cotton on 1.33 million planted acres.

Coley begins harvesting his 1,500-acre crop in late September, the bulk of it finished in October or November.

“Georgia is fortunate to have cotton back as a major crop,” Coley says. “Because cotton is a highly intensive crop, it’s very good for the local economies. Cotton creates more jobs – from the gin to the warehouse to the shops – than any other crop.”

The cotton gin, patented by Eli Whitney, transformed the cotton industry. The gin, short for “engine,” could do the work of processing cotton 10 times faster than by hand, making it possible to supply large quantities of cotton fiber to the textile industry. That spurred a huge increase in cotton prices for farmers, making cotton a leading cash crop in the U.S.

Coley has seen some jobs move overseas as labor costs in the U.S. rose and labor costs were cheaper in less developed countries.

“Now, 75 to 80 percent of our cotton crop is exported,” Coley says. “India and China are major importers, as well as Mexico and Turkey. The mills have gone there because of fewer regulations and cheaper labor. China has been a world leader in the textile industry, but they’re actually losing some to other Asian countries that have cheaper labor costs, like Thailand and Vietnam.”

The Future of Cotton

For Georgia farmers like Coley, the outlook for raising cotton isn’t all that positive, but Coley expects it to improve with time. Worldwide there’s more cotton than needed, and the carryover puts a damper on prices. Both India and China had good cotton crops in 2011. At the same time, consumer demand worldwide dropped as the economy slowed.

“Prices aren’t so good for cotton compared to the value of corn or soybeans or wheat,” Coley says. “But prices will come back – they always do.”

As for Coley, he’ll not only be raising cotton, but wearing it.

“I try to wear cotton most of the time – khakis and a plaid cotton shirt.”